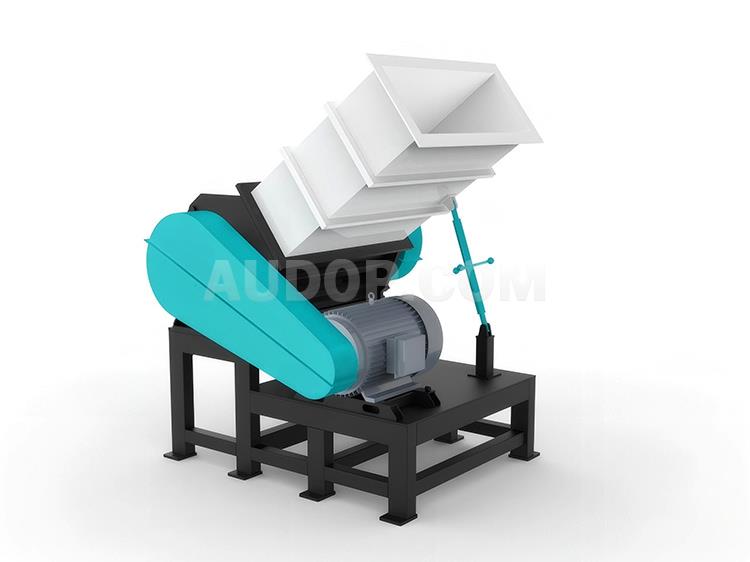

Pipe and Profile Crusher

- Low Energy Consumption: Integrates centrifugal crushing, impact crushing, and extrusion crushing; saves up to 40-50% more energy than other types of mechanical crushers. Low Energy Consumption: Combines centrifugal, impact, and extrusion crushing technologies, achieving 40-50% higher energy efficiency compared to other industrial mechanical crushers.

- High Fineness: Equipped with a self-diversion classification system, the product fineness is ≥2500 meshes. High Fineness Output: Equipped with a self-diversion grading system, ensuring the crushed product fineness reaches ≥2500 meshes, meeting high-precision recycling requirements.

- Large Feeding Range: The feeding particle size is ≤50mm, and the materials only need to go through one-stage coarse crushing equipment. Wide Feeding Capacity: Accepts materials with particle size ≤50mm, requiring only one-stage coarse crushing, simplifying the production line configuration for factories.

- Low Wear Rate: Wearing parts in the crushing section are made of new composite wear-resistant materials, ensuring long service life. No pollution is generated when processing materials with Mohs hardness ≤5, suitable for clean production lines.

- Strong Mechanical Stability: Can operate continuously for 24 hours for long-term production. High Mechanical Stability: Capable of 24/7 continuous operation for long-term industrial production, ensuring stable output for manufacturing lines.

- Can crush acicular materials, achieving a finished product aspect ratio of 15:1; no temperature rise during the crushing process, suitable for crushing heat-sensitive materials; can disperse sintered and agglomerated ultra-fine materials, with a particle size recovery rate of 100%; has a particle shaping function to effectively improve bulk density. It can crush materials with fibrous structures; crush materials with high moisture content (with drying function); and crush materials with strong viscosity. Versatile Crushing Capabilities: Can crush acicular materials (finished product aspect ratio 15:1); no temperature rise during crushing, ideal for heat-sensitive materials; disperses sintered agglomerated ultra-fine materials with 100% particle size recovery; has particle shaping function to enhance bulk density. It can also crush fibrous materials, high-moisture materials (with built-in drying function), and high-viscosity materials.

- Negative pressure production, no dust pollution, and a good working environment. Negative Pressure Operation: No dust pollution during production, creating a clean and safe working environment for factory workshops.

- High degree of automation, strong stability, and easy operation. High Automation Level: Features strong stability and simple operation, reducing the need for skilled operators and lowering labor costs for enterprises.

Overview

The pipe crushing machine is uniquely designed with a circular pipe feeding port for pipe material crushing, which facilitates the feeding and crushing of long-length pipes and improves work efficiency. This pipe crusher with a specialized circular inlet is optimized for long pipe crushing, enhancing operational productivity effectively.It can be optionally equipped with a suction fan and a storage barrel to form a pipe crushing and recycling system, which can give full play to the recycling efficiency. Optional accessories like a material suction fan and storage bucket can be added to form a complete pipe crushing and recycling system, maximizing the recycling performance for industrial use.

This machine is a waste plastic recycling equipment, suitable for crushing and granulating waste and defective injection gates of engineering plastics, as well as various thermoplastics and rubbers. As a professional waste plastic recycling machine, it is applicable for crushing and granulating waste/defective engineering plastic injection sprues, along with all types of thermoplastics and rubbers.This machine is not suitable for crushing various soft plastics and foam plastics. Note that this crusher is not designed for crushing soft plastics or foam plastics.

Product Applications:

It is mainly suitable for crushing various plastic profiles and pipes; for longer plastic pipes, there is no need for cutting and segmenting, and continuous feeding can be achieved at one time. Mainly used for crushing various plastic profiles and pipes; long plastic pipes can be fed continuously without pre-cutting, saving time and labor in the production process.Such as plastic doors, plastic pipes, plastic plates, window frames, wire troughs, sheets, etc. Examples include plastic doors, plastic pipes, plastic sheets, window frames, cable trays, and plastic panels.

This model can realize automatic feeding; the entire pipe is put into the machine and crushed automatically. This pipe crusher model enables automatic feeding—whole pipes are fed into the machine and crushed completely without manual intervention.It is equipped with a fan device for conveying crushed materials; qualified crushed granules are extracted from the machine by a suction fan, facilitating bagging and warehousing. Equipped with a fan-based crushed material conveying system, qualified granules are sucked out of the machine by a suction fan, making bagging and storage convenient for factory operations.It is equipped with an opening device, and the large-sized SWP model is equipped with an independent electrical box control cabinet. It comes with an easy-opening mechanism, and large SWP series models are furnished with an independent electrical control cabinet for safe and convenient operation.It is extremely convenient to operate and maintain, and is an ideal model for crushing various pipes and profiles. With easy operation and maintenance, it is an ideal crusher for various pipes and plastic profiles in industrial settings.The wearing part of the crusher is the blade, which will inevitably wear out after long-term use. The blade is the wearing part of the crusher, and it will wear over extended use—regular inspection is recommended.We usually use 9CrSi alloy steel blades; compared with ordinary materials, they have stronger wear resistance and impact resistance, and after long-term use, the blunt blade edges can be sharpened and reused, greatly reducing costs. We usually equip it with 9CrSi alloy steel blades, which offer better wear resistance and impact resistance than ordinary materials. Blunt edges can be sharpened for repeated use, significantly reducing replacement costs for manufacturers.According to different customer requirements, imported blades can also be equipped to better improve the machine performance. Customization options are available—imported blades can be equipped upon customer request to further enhance the crusher's performance for specific production needs.

Maintenance:

- The pipe crusher should be placed in a well-ventilated location to ensure the heat dissipation of the motor and extend its service life. 1. Install the pipe crusher in a well-ventilated area to ensure effective heat dissipation of the motor, prolonging the motor's service life for long-term use.

- Lubricating oil should be regularly added to the bearings to ensure lubrication between the bearings.

- Regularly check the blade screws, fasten the screws of the moving blade and fixed blade with tools, and strengthen the fixation between the blades and the tool holder. 3. Regularly inspect blade screws; use tools to fasten the screws of moving and fixed blades to enhance the stability between blades and the tool holder.

- To ensure the sharpness of the blade cut, the blades should be checked frequently to maintain their sharpness, reducing unnecessary damage to other components caused by blunt blade edges. 4. Frequently inspect the blades to maintain their cutting sharpness, avoiding unnecessary damage to other parts due to blunt edges.

- When replacing the blades, the gap between the moving blade and the fixed blade is preferably 0.8mm for crushers above 20HP, and 0.5mm for crushers below 20HP. The thinner the recycled material, the appropriately larger the gap can be adjusted. 5. When replacing blades, the optimal gap between moving and fixed blades is 0.8mm for crushers ≥20HP and 0.5mm for crushers <20HP. For thinner recycled materials, the gap can be adjusted slightly larger.

- Before restarting the machine, the remaining crushed materials in the machine chamber should be cleared first to reduce the starting resistance. The inertia cover and pulley cover should be opened regularly to clean the ash outlet under the flange, as the powder discharged from the crusher chamber may enter the rotating shaft bearing. 6. Before restarting, clear residual crushed materials in the machine chamber to reduce starting resistance. Regularly open the inertia cover and pulley cover to clean the ash outlet under the flange—preventing powder from the crusher chamber from entering the rotating shaft bearing.

- The machine should be well grounded. 7. Ensure the machine is properly grounded to ensure safe operation in industrial environments.

- Regularly check whether the crusher belt is loose and tighten it in time. 8. Regularly inspect the crusher belt for slack and tighten it promptly to maintain stable machine performance.

Technical Parameters

Technical Parameters

Model | Knife Roller Diameter(mm) | Noving Cutter (pieces) | Stationary Kknife (pieces) | Screen Mesh Aperture (mm) | Feed Inlet Diameter(mm) | Output (kg/h) | Power (kw) |

| SWP-450 | 450 | 5 | 2 | 10-12 | 375×320 | 350-500 | 22 |

| SWP-630 | 630 | 9 | 2 | 10-16 | 375×320 | 400-800 | 30 |

| SWP-750 | 750 | 3 | 2 | 10-16 | 375×320 | 600-900 | 45 |

Your requirements are the basis for our development and a daily challenge to bring to fruition, please do not hesitate to inquiry us.

Plastic Crusher

- Good Crushing Effect: The high-speed rotating blades or hammers of the Plastic Shredder can apply multiple forces to crush plastic, turning it into small pieces quickly.

- Easy Operation: The entire operation process of the Plastic Shredder can be completed only by putting the plastic to be crushed into the feed inlet and starting the electric motor.

- Wide Application Range: The Plastic Shredder is suitable for the recycling and reuse of various types and forms of plastic.

Crushing And Milling Production Line

- Closed dust treatment significantly reduces dust in the workshop, making the miller an ideal choice for a clean production environment.

- Adjustable electromagnetic vibration feeding ensures more stable current when the miller is in operation, improving the overall running stability of the crushing and milling production line.

- A closing fan is installed at the discharge port of the cyclone separator, which greatly reduces dust leakage and enhances the environmental protection performance of the miller.

- The use of high-quality bearings, oil seals and high-grade lubricating grease ensures the long-term normal operation of the miller, reducing maintenance costs for users.

- The overall water cooling of the milling chamber ensures that the properties of materials do not change during the crushing process, which is crucial for maintaining the quality of recycled materials in the crushing and milling production line.

- It has high production efficiency, with a significantly higher output compared to old-fashioned turbine millers, which can effectively improve the production capacity of the crushing and milling production line.

- The milling chamber door can be opened, allowing for quick cleaning of the milling chamber and fast and convenient replacement of moving knives and gear plates, saving maintenance time for the miller.

- High-quality accessories, strict manufacturing requirements and a rigorous manufacturing process ensure the quality of the miller, providing reliable equipment support for the crushing and milling production line.

- It has a simple structure, is reliable and durable. The modular design allows the miller to be installed in different directions according to the size of the workshop, enhancing the flexibility of the crushing and milling production line layout.

Medium-Speed Machine-Side Plastic Crusher

- Low noise and no dust emission—creating a clean and comfortable working environment for production line engineers and workshop staff.

- Strong crushing capacity and safe, stable operation—effectively handling large quantities of plastic runner scraps and ensuring consistent processing quality for factory production lines.

- Adopting axial sprocket drive, it reduces bearing wear. Compared with traditional crusher structures, it operates more stably and reliably, reducing the frequency of equipment failures and lowering maintenance costs for enterprises.

- Equipped with an adjustable pneumatic material pushing device, it facilitates easy feeding, reduces the jumping and impact of thick materials and block materials during crushing, and avoids material blockage. This also helps reduce noise, ensures more stable crushing, and improves crushing output—meeting the high-efficiency production demands of plastic manufacturing factories.

- It has a solid and well-made rotor device. The optimally designed smooth rotor and stepped rotor blades increase cutting torque, improve crushing effect, and help crush hard-to-break, thick ?? materials. This expands the application scope of the crusher, making it suitable for various plastic waste treatment scenarios in different industries.